Concepts to develop bio-inspired systems on the basis of sustainable systems in living things

Dioxygen molecule is indispensable for human life. We take in dioxygen molecule from the air by breathing to supply it to the brain and other organs. Energy is generated by combining dioxygen molecule with sugars and lipids, and this is the so-called “assimilation”. Oxidation reactions are essential not only for the assimilation in living organisms but also for the chemical reactions in the industrial productions of a variety of chemicals.

For example, phenol, which is used in a wide range of industrial applications such as agricultural chemicals and pharmaceuticals, housing, automobiles, textiles, home appliances, and electronics, is made by oxidizing benzene. An industrial process called the “cumene method” is the main production method, where benzene is oxidized to cumene hydroperoxide and it is converted to phenol and acetone. However, the cumene method, which is the main type of phenol synthesis today, has many problems. First, the phenol yield from benzene is as low as 5%. Cumene hydroperoxide, which is produced as an intermediate product, has explosive and corrosive properties. And the process is not environment-friendly because it is necessary to use a high-temperature, high-pressure environment and sulfuric acid. Prof. Kodera, an expert in bioinorganic chemistry, has brought new insights to oxidation reactions through “bio-inspired” learning from the activities and structures of living organisms.

The word “sustainable” is frequently heard in recent years, and according to Prof. Kodera, the system of life is the most sustainable. “When you oxidize starting materials to produce some compounds in industrial chemistry, you may need heat as high as several hundred degrees, but in the body of human beings we can do it at about 36-37℃. That’s why living things have existed for a long time, and that’s why we study from a bio-inspired perspective.”

Realization of highly efficient phenol synthesis with binuclear copper complex

Methane is considered a highly inert substrate because it is extremely difficult to oxidize artificially and selectively. However, in the biological systems, the selective oxidation of methane to methanol is easily catalyzed by methane monooxygenase. Why does the oxidation reaction, which requires much effort to produce artificially, occur easily in nature? Therein lies the key to solving the mystery in the living body.

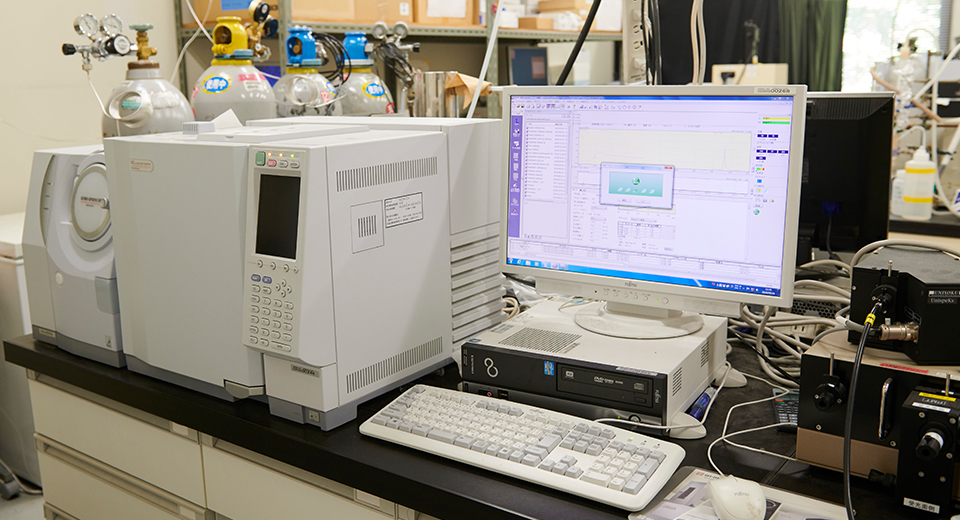

“When you cultivate soil containing methane, methane-utilizing bacteria grow. They live by digesting methane and have an enzyme called methane monooxygenase that oxidizes methane in the body. Methane monooxygenase is a metalloenzyme with binuclear iron as the active center. In my research, we have succeeded in producing phenol with high efficiency by using a binuclear copper complex that mimics this structure.”

The existence of methane-utilizing bacteria and methane monooxygenase has been known for a long time. While other researchers have tried to use bacteria themselves as catalysts for oxidation reactions, Prof. Kodera modeled the action of bacteria’s enzymes and made a catalyst artificially. This is the unique feature of his research. The binuclear copper complex he has made enables a more efficient and highly selective oxidation reaction as a model of methane monooxygenase. When phenol was produced from benzene using a binuclear copper complex instead of the aforementioned cumene method, the yield was more than four times higher.

In addition, since the oxidation reaction occurs under normal temperature and pressure, it is more environment-friendly than the conventional method. Since apparatus to generate a special environment such as high temperature and high pressure is not required, the energy consumption required for phenol synthesis is greatly reduced. “Methane hydrate is attracting attention as an alternative to petroleum, but it would be easier to handle if it could be turned into liquid methanol by oxidizing it rather than methane, which is a gas. This research is expected to be applicable to high value-added oxidation reactions such as methanol production by methane oxidation.” Thus, the binuclear copper complex is expected to be useful as a catalyst in a new production technique for oxidation reaction.

High selectivity of metal complexes to help develop anti-cancer drugs without side effects

Prof. Kodera has recently expanded his study on oxidation reactions into new fields. “Our research aimed to create high-performance catalysts and activating oxygen, but now we consider that the catalysts we created can be used effectively in living organisms. For example, cancer cells occur when normal cells in our body mutate. Anti-cancer drugs used for treatment have strong side effects because they work on both normal cells and cancer cells to the same extent. If we can develop a mechanism that allows drugs to selectively work only on cancer cells, it should be possible to develop drugs with no side effects. Cancer cells have a unique environment different from normal cells, so if we can develop a highly selective oxidation reaction of the metal complex I have studied so far in a form suitable for pathology, it will be useful in the medical field as well.”

His “bio-inspired” approach will not change, no matter how much the research area expands. “In order for humanity to survive for a long time, it is essential to build a sustainable system. About 80% of the atmosphere of the newly-formed Earth was carbon dioxide. Later, cyanobacteria emerged, and oxygen was produced by photosynthesis. What is important is that water is used as a reducing agent in addition to the oxygen produced. The oxidation reaction using water as a reducing agent is a lean ecosystem. If this mechanism can be integrated into an industrial system, it will help create a more sustainable world. This is the ultimate goal of research on oxidation reactions.” Prof. Kodera is constantly studying and learning from living things. His future activities deserve close attention.