Interview with researchers 19

From the borders of

electric machines and

computational science:

Contributions to global energy savings

by optimizing the efficiency

of electric machines

- Interview Yasuhito Takahashi

- Professor,

Department of Electrical Engineering, Faculty of Science and Engineering

Designing high-efficiency electric machines is an essential energy measure, from their structure to their magnetic materials.

As the information revolution progresses worldwide, it is essential to secure a stable, environmentally friendly energy supply and ensure efficient use of this energy. The key to energy savings is optimizing the efficiency of motors and other devices used within electric vehicles, household appliances, etc. Professor Takahashi is actively involved in the research focused on improving the efficiency of electric machines for different uses, such as motors and generators, made by a variety of manufacturers, under the banner of “technology that can be shared in common.”

“Work is underway globally to improve the efficiency of electric machines, with the goal of saving energy,” says Prof. Takahashi. “For example, efficiency standards exist for industrial motors, such as three-phase induction motors. Products that do not meet these standards cannot be marketed. Ever stronger demands for high energy savings are certain to occur in the future, making greater efficiency a key theme,” he adds.

Prof. Takahashi’s work considers the perspectives of various disciplines, notably power magnetics and computational electromagnetics. The operational principle for electric machines is the use of magnetic energy. A variety of magnetic materials are used to ensure that a large amount of magnetic energy can be employed with even small amounts of electric current. Power magnetics is the research field for magnetic energy applications and includes measuring magnetic properties of magnetic materials and modeling of them for electric machine design. Computational electromagnetics is the domain where computers are used to model and simulate electric machines based on the complex magnetic properties of magnetic materials. This is an essential technology for the evaluation of machine performance as magnetism plays a major role in the operation of electric machines. This makes it indispensable for all efforts aimed toward increasing the efficiency of electric machines.

Contributions toward improving development processes and products via tie-ups with companies and academia

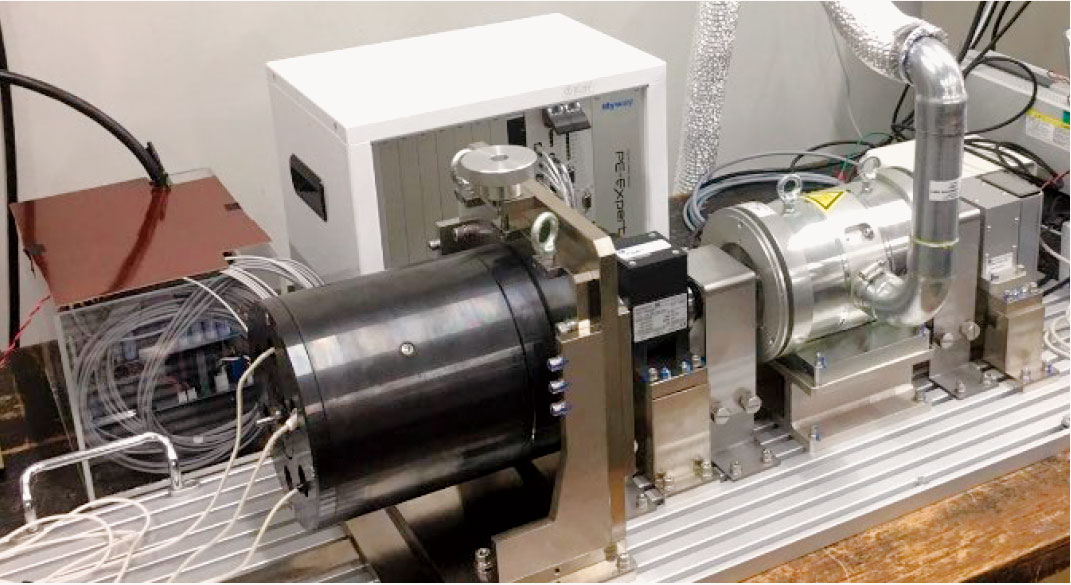

With his research focused on electric machines, Prof. Takahashi is involved in active collaborations with private companies. One such project involves the evaluation of energy loss within the frame of a permanent magnet synchronous motor

“When thinking about energy loss in a motor, there are many uncertainties involved, especially with losses that occur within the frame, as it is not impacted by electrical characteristics,” explains Prof. Takahashi. “With the cooperation of the company, we measured the magnetic properties of the frame material (cast iron) and performed simulations to evaluate the energy loss of the motor under various operating conditions.”

They found that when the motor rotated at high torque conditions (i.e., when substantial power was needed, such as during startup or acceleration), a large amount of current flowed. Therefore, a portion of the magnetic flux flowing within the stator core of the machine leaked out, resulting in significant losses within the frame. Meanwhile, under low torque conditions, such as when the motor was rotating at high speeds, the losses remained low owing to little magnetic flux leakage.

“Generally, in inverter-driven motors, energy losses increase due to the effects of harmonics included within the inverter’s output voltage waveform. These harmonics are called “carrier harmonics.” However, our research revealed that frame losses were mostly unaffected by carrier harmonics. Now, our next step is to determine countermeasures for the substantial frame losses that occur under high torque conditions,” says Prof. Takahashi.

Prof. Takahashi is also vigorously engaged in joint research efforts with academia, an endeavor that has enabled him to propose novel methods for the simulation of squirrel-cage induction motors.

“Much research is performed today on model order reduction, a method for expressing the behavior of complex, large-scale systems at high speed and high precision. The Cauer ladder network (CLN) method is one of the model order reduction methods that has been developed by Japanese researchers and has now garnered worldwide attention,” elaborates Prof. Takahashi. “Researchers at Kyoto University applied the CLN method for model order reduction of a squirrel-cage induction motor and investigated its effectiveness. Our group further improved upon the results of this study. In our work, we focused on the air-gap between the fixed and rotating parts of the motor because magnetic energy density is concentrated there. In this way, we were able to extract only the important components of air-gap magnetic flux density waveforms while achieving a major reduction in computation time compared with that of the conventional finite element method (FEM),” he highlights.

When using the CLN method, the reduced model is obtained in the form of a simplified “ladder” of electrical circuits. These can be intuitively understood by electrical engineers, who are familiar with circuit diagrams. This makes the method highly practical and useful.

Prof. Takahashi emphasizes that the varied possibilities of the CLN method could lead to reducing the development time for electrical systems, including control systems for inverters and electric machines, such as squirrel-cage induction motors, and improving the efficiency of the system simultaneously.

Pursuing challenges while incorporating new techniques to help resolve societal issues

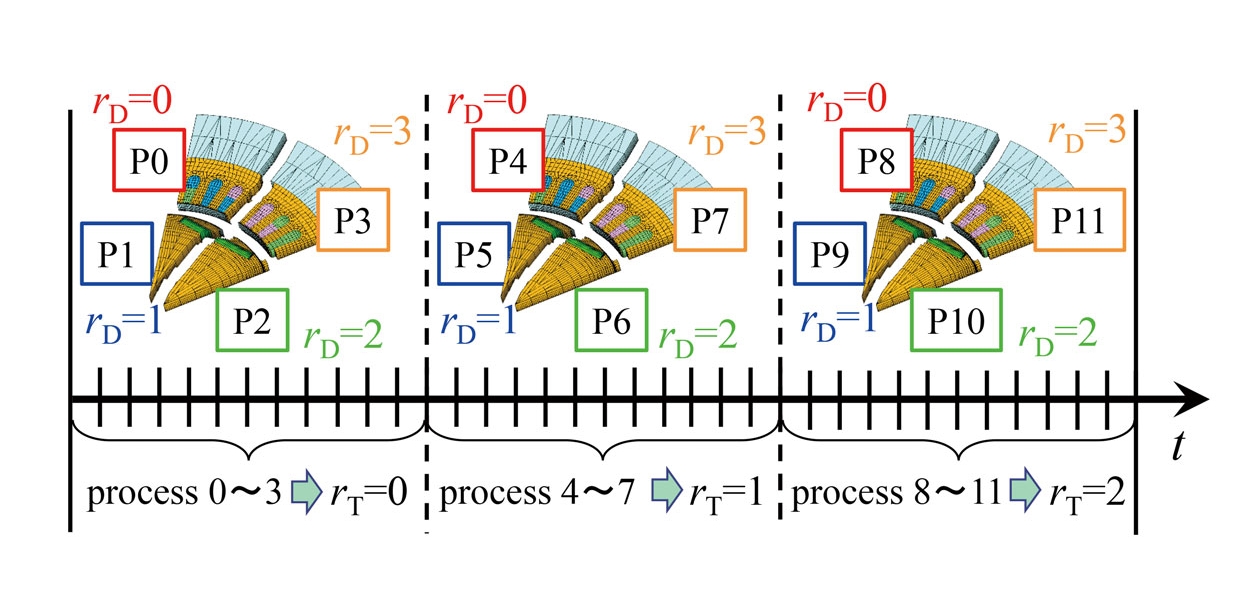

Prof. Takahashi is also engaged in research focusing on methods of analyzing motor operation using high-performance computing technologies. He explains, “Spatial parallel computing tools are available in commercial software, and this approach is called a parallel in-space (PinS) approach. I’m engaged in a method of parallel computing that involves combining ‘space’ with ‘time.’ Here, the calculation domain is divided spatially into several smaller domains, and different time intervals are assigned to each of these domains. The parallel computing method in time axis directions is called the ‘parallel-in-time’ (PinT) method. When used together, this technology is called parallel-in-space-and-time (PinST)method.” [Note 1]

To understand this, think about the production of a movie. A single movie comprises numerous scenes and multiple teams proceed simultaneously with the filming at different spatial locations and times in an order that is different from the movie’s progression. In the end, the shots are integrated into a single movie according to the intended progression. This method is clearly more efficient than having one team film each scene in the order they appear in the final movie.

“To ensure that the results for PinT processing are well connected front to back, we developed a novel correction method. We have confirmed high parallel efficiency, even in a highly parallel computing environment, using 10,000 processes or more. Little research has been done on parallelizing across time, and other researchers in computational science have evaluated our work as ‘quite interesting.’ Even for electric machines where the number of freedoms is not so large, it is necessary to consider the effect of carrier harmonics accurately in performance evaluations of inverter-driven motors. This requires the use of efficiently small time step size, which results in huge computational costs. We thus think that the PinST method is fairly effective in the analysis of inverter-driven motors,” says Prof. Takahashi.

In a PinS computing method using several thousand or more processes, it is not easy to achieve good parallel performance. Accordingly, Prof. Takahashi predicts that combining spatial with temporal parallelization will undoubtably become a groundbreaking approach.

“I did not originally have a strong interest in electric machines when I was a student. But the classes that I took in university demonstrated to me the broad scope of their usage and applications, and I had a strong sense that this was a field where I might be able to make significant contributions to society. These feelings led me to my current research. In fact, I was not good at computers, either. It was only as I progressed in my research on electric machines that I had more opportunities to use computers. Through this experience, I came to believe that both computers and electric machines were interesting domains. In the future, I intend to continue tackling challenges while proactively incorporating new techniques and technologies. I believe that my research will be linked with resolving some of our current energy issues,” concludes Prof. Takahashi.

While Prof. Takahashi realizes that energy problems may not be solved from the perspective of power generation alone, he emphasizes the importance of addressing energy consumption, for example, using high-efficiency electric machines. He wishes to continue tackling new challenges on the “borders” between electric machines and computational science.

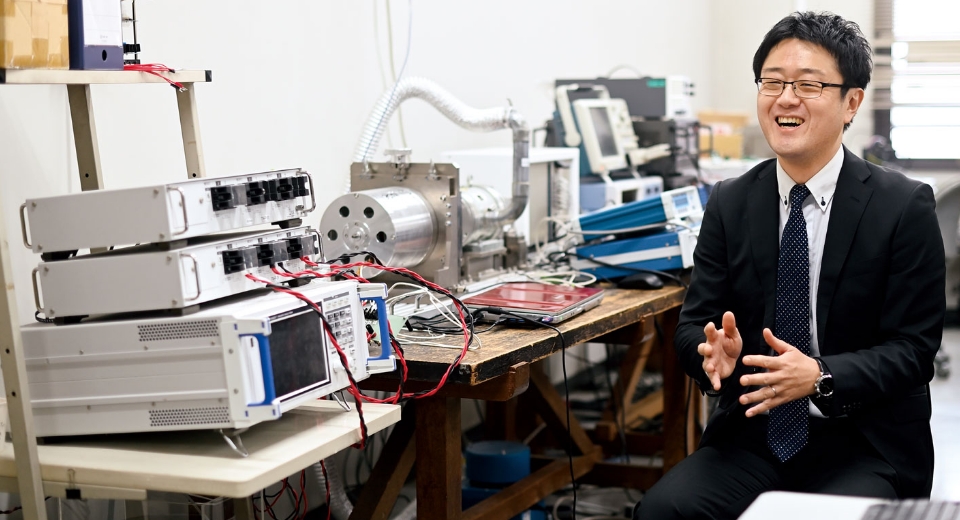

Inverter, controller, permanent magnet synchronous motor, and load in Dr. Takahashi’s research lab

[Fig. 1 text] The case where time steps per cycle=36, number of time domains=3, number of spatial domains=4, and number of processes=12

(*Note 1) “Inverter”: An apparatus for converting from direct current (DC) to alternating current (AC). By changing frequencies and voltages, the inverter is used for adjustments of motor rotation speeds and rotational power (torque).

(*Note 2) “Harmonics”: Sinusoidal waves that may be the cause of vibration, noise, etc., in an electric motor.