Research News: Novel Ratchet with Geometrically Symmetric Gear Driven by Asymmetric Surface Wettability

August 26, 2024

Researchers have developed a novel ratchet mechanism that utilizes asymmetry in surface wettability and resembles the biological Brownian ratchets

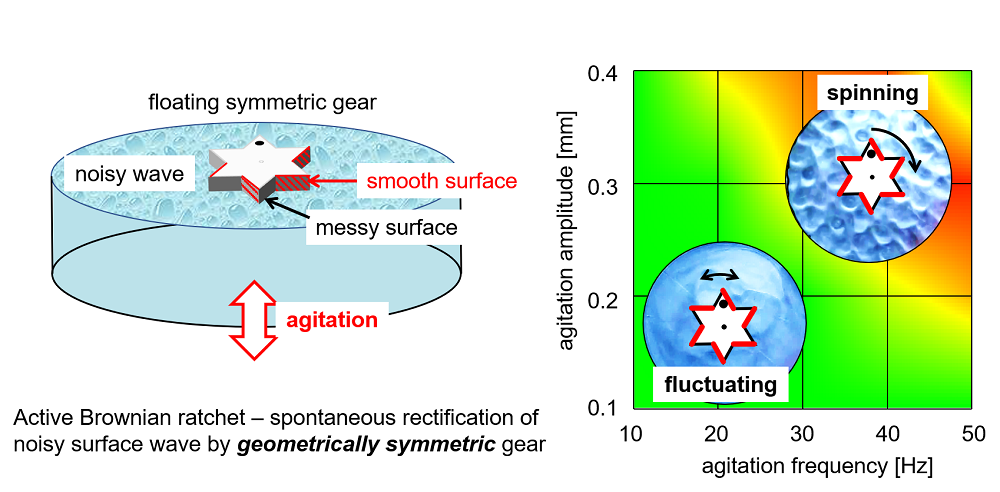

Conventional ratchet mechanisms involve a geometrically asymmetric gear for realizing the ratcheting mechanism. In a new study, researchers have now developed a novel ratcheting mechanism based on the asymmetry of surface wettability and it uses a geometrically symmetric gear. This innovative mechanism resembles the Brownian ratchets, which have been proposed for understanding the motion of molecular motors in biological systems and can pave the way for novel energy-harvesting technologies.

The ratchet mechanism is a fascinating energy-conversion system that converts disorderly or random motion into orderly, directed movement through a process known as spontaneous rectification. It is a critical component of mechanical systems, typically consisting of a gear and a pawl, which restricts the movement of the gear in one direction. In biological systems, the concept of a Brownian ratchet has been proposed to help understand the mechanism of molecular motors, where chemical reactions rectify the random thermal motion of molecules.

According to the second law of thermodynamics, uniform thermal fluctuations cannot spontaneously generate regular motion. Practical Brownian ratchets therefore require nonequilibrium fluctuations to function. Physiological chemical reactions in biological systems modulate thermal motion and are known to generate nonthermal fluctuations, which may be crucial for the ratchet mechanism. Moreover, identifying the types of nonequilibrium noisy motions that can be rectified by a ratchet mechanism is an intriguing and fundamental question in science, facilitating the development of novel energy-harvesting technologies. The Feynman–Smoluchowski ratchet is a classic example of an active Brownian ratchet, which has led to numerous ratchet motor studies. In most of these studies, the ratchet mechanism involves using a geometrically asymmetric ratchet to rectify nonthermal fluctuations derived from mechanical vibrations.

In a breakthrough, a team of researchers from the Department of Chemical Engineering and Materials Science, Doshisha University, led by a Ph.D. student Miku Hatatani along with Associate Professor Yamamoto Daigo and Professor Akihisa Shioi, developed a novel ratchet mechanism based on the asymmetry of surface wettability using a geometrically symmetric gear. “We realized a new model of an active Brownian ratchet motor that utilizes the surface-energy profile for the ratchet mechanism. This is quite different from conventional geometrically asymmetric ratchets and is closer to the biological one,” explains Hatatani. Their study was published in the journal Scientific Reports on July 18, 2024.

The innovative ratchet mechanism developed by the team involves a geometrically symmetric star-shaped gear made of acrylonitrile butadiene styrene (ABS) resin, with six triangular teeth. Parafilm is attached alternatively to the right side of each tooth, as viewed from the front face of the gear, resulting in a difference in surface wettability between the two faces of the teeth. The gear was tested by placing it in a water-filled petri dish, with its front facing a camera mounted on top of the dish. The gear was fixed with a push pin through a drilled hole in its center. The petri dish was placed on a vibrating disk that oscillated vertically at a pre-determined frequency, producing random fluctuations in water.

The gear with the parafilm demonstrated a one-way spin in the waterbed with vertical oscillations in a restricted range of frequency and amplitude. In contrast, the gear without the parafilm did not exhibit a one-way spin for any frequency or amplitude. The one-way spin for the parafilm gear was determined by the chirality of the gear, meaning that the spinning direction was opposite when viewed from different faces. It exhibited a clockwise spin direction when viewed from the front face, and vice versa. Interestingly, the gear showed fluctuations in both directions at shorter timescales but at longer timescales, it showed a one-way spin.

The researchers investigated the mechanism of this innovative ratchet motor and found that its unique motion is generated by a stochastic process with a biased driving force. This biased driving force was produced by the difference in interactions of the water waves, or surface wettability, between the highly smooth parafilm face and the relatively rough non-parafilm face of the gear teeth.

Highlighting the potential of this study, Hatatani remarks, “Considering that a molecular ratchet works on an asymmetric potential with cyclic variation, our system may provide a breakthrough in generating a new ratchet motor design. We believe that it can lead to the development of energy-harvesting technologies that can, for example, enable directed transport from vibrational noise and a micrometer-sized motor, acting in a microfluidic device.”

Looking ahead, she optimistically concludes, “We hope that our work can inspire future studies that will ultimately lead to the discovery of the missing link between science and technology for realizing real Brownian ratchets and consequently, lead to novel energy-harvesting technologies.”

Surface-energy ratchet mechanism

The proposed ratchet mechanism utilizes the asymmetry in surface wettability between the smooth and rough faces of the teeth of a geometrically symmetric gear to achieve ratcheting motion.

Image courtesy: Miku Hatatani from Doshisha University

Image license: Original content

Usage Restrinctions : Cannot be reused without permission

Reference

| Title of original paper | Surface-energy ratchet motor with geometrical symmetry driven by biased random walk |

| Journal | Scientific Reports |

| DOI | 10.1038/s41598-024-67383-1 |

Funding information

This research was funded by Japanese Society for the Promotion of Science (JSPS) to A.S.; (KAKENHI grant number JP22K03560) and was supported by JST, the establishment of university fellowships towards the creation of science technology innovation, and JST SPRING to M.H.; Grant Number JPMJFS2145 and JPMJSP2129.

EurekAlert

https://www.eurekalert.org/news-releases/1054930

Profiles

Miku Hatatani

Ph.D.student in the Department of Chemical Engineering and Materials Science at the Graduate School of Doshisha University

Miku Hatatani is currently a Ph.D. student in the Department of Chemical Engineering and Materials Science at the Graduate School of Doshisha University. She is also a member of the Laboratory of Molecular Chemical Engineering at Doshisha University. Her research interests include biological ratchet motors, Brownian ratchets, and a broad interest in nonequilibrium phenomena and nonlinear science.

Akihisa Shioi

Professor, Faculty of Science and Engineering Department of Chemical Engineering and Materials Science

Akihisa Shioi serves as a Professor at Doshisha University’s Department of Chemical Engineering and Materials Science. His research group primarily focuses on projects in the area of chemical engineering, colloid and interface science, physical chemistry, nonequilibrium science, nanotechnology, energy chemistry, manufacturing technology, and natural sciences. Prof. Shioi is a well-cited researcher with over 100 research articles and 10 books to his credit.

Media contact

Organization for Research Initiatives & Development

Doshisha University

Kyotanabe, Kyoto 610-0394, JAPAN

CONTACT US